check

check

check

check

check

check

check

check

check

check

On high-speed automated production lines, every tiny part is crucial to assembly efficiency and product quality.

KJT ring proximity switches, with their high-precision detection capabilities and adaptability to various scenarios, provide a stable and reliable sensing foundation for the supply of small metal parts on production lines.

01 Multiple Aperture Selection · Dynamic and Static Dual Modes

Based on the size of different parts and process cycles, the ring proximity switch offers multiple sensing apertures, supporting free switching between dynamic and static detection modes to meet diverse needs from rapid passage to stationary detection.

- Dynamic Detection: Suitable for high-speed feeding and instantaneous passage scenarios

- Static Detection: Suitable for dwell detection, presence confirmation, and accurate counting

- Adjustable Sensitivity and Pulse Extension: Adaptable to metal parts of different materials, sizes, and speeds. This ensures the device maintains excellent recognition performance even under complex operating conditions.

02 Micrometer-level resolution · Millisecond-level response

Built-in high-performance signal processing unit, featuring:

- Micrometer-level resolution: Accurately identifies tiny metal parts

- Millisecond-level response speed: No missed detections, no delays

- Anti-interference algorithm optimization: Maintains stable detection even under vibration, light, and dust

Achieving both precision and high speed, providing strong support for flexible and stable material feeding.

03 Specialized inspectors for various types of small items

Ring-shaped proximity switches play a crucial inspection role in precision feeding systems, providing clear, quantifiable, and stable monitoring capabilities for various types of small metal parts:

Screw Inspection

Each passing screw is accurately counted and its existence confirmed, eliminating potential problems such as missing screws or overtightening.

Spring Inspection

Springs are stably counted and clearly verified upon passing, ensuring continuous assembly processes and smooth feeding rhythms.

Steel Ball Monitoring

Even within a closed feeding pipeline, the flow status of steel balls can be reliably sensed, providing real-time material feedback and ensuring the stable operation of the precision feeding system.

04 Highly Adaptable Design for Precision Assembly

KJT ring proximity switches not only emphasize detection capabilities but also focus on industrial field applicability:

- Compact design for easy integration

- Anti-fouling design suitable for oily and dusty mechanical environments

- High repeatability accuracy, suitable for long-term continuous detection

- Seamless integration with PLCs, feeders, and counters

Easy deployment for both standalone devices and entire production lines.

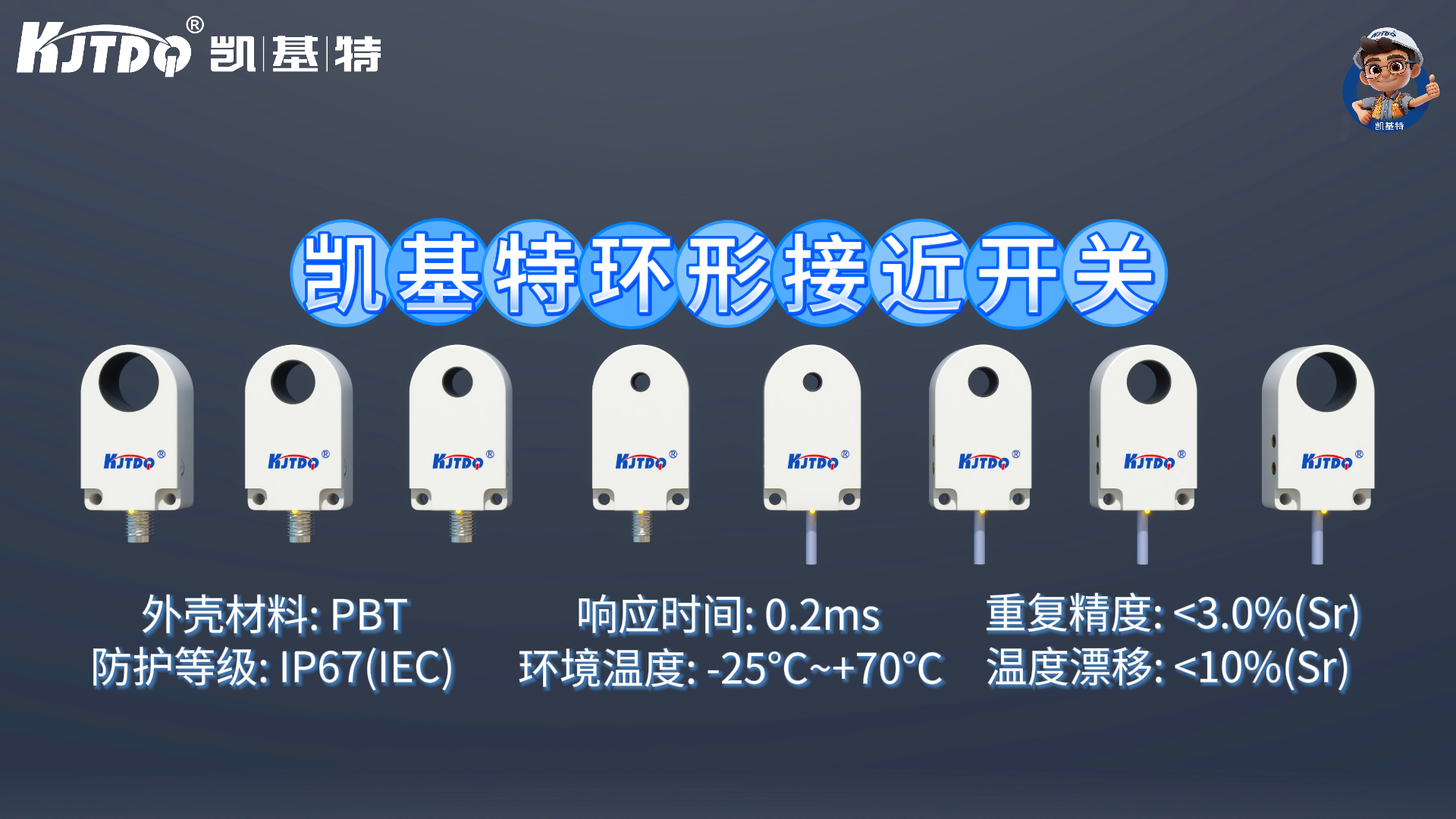

KJT Ring Proximity Switch

Precisely senses every small component, safeguarding precision feeding systems.