check

check

check

check

check

check

check

check

check

check

In the torrent of industrial production, precise control of material dynamics is the cornerstone of safety and efficiency.

KJT Rotary Paddle Level Switch

With a precision mechanical structure at its core and made of corrosion-resistant materials, it can easily adapt to harsh working conditions, ensuring safe monitoring of every detail.

Working Principle | Precise Response, Intelligent Monitoring

✅ When not in contact with material—the blade rotates freely, and the motor continues to run, ensuring normal system operation.

✅ When material accumulates—the blade is obstructed, the motor stops immediately, and outputs a signal to accurately feedback material level information, preventing overload and blockage risks.

Product Advantages | High Efficiency, Stability, Flexible Adaptability

✔ Corrosion-resistant structure—adapts to complex environments such as high humidity and high dust levels.

✔ High-sensitivity detection—effectively prevents equipment damage and improves production efficiency.

✔ Customized solutions—multiple specifications are available to meet different working conditions.

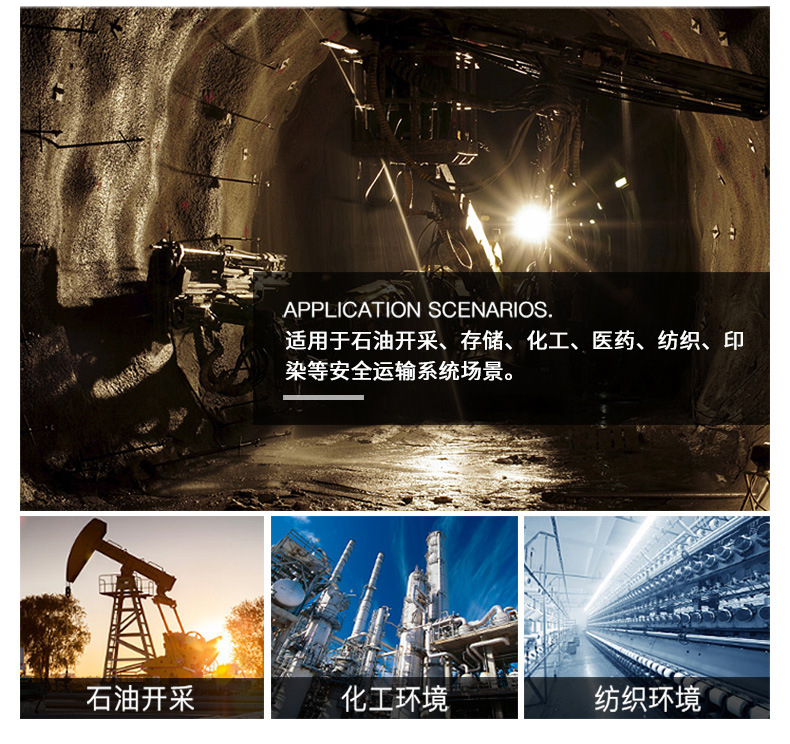

Wide Applications | Adaptable to Multiple Industries

✅ Chemical Industry: Precisely monitors powder and granular materials to ensure production safety.

✅ Grain Storage and Transportation: Real-time monitoring of material accumulation to prevent storage blockages.

✅ Building materials industry: Stable testing of large-particle materials such as cement and sand, improving conveying efficiency.

KJT – Safeguarding Your Conveyor Systems! KJT rotary paddle level switches promote efficient production and ensure equipment safety!

For more information on belt conveyor protection devices, please visit our website:

Contact us for more professional sensor support case studies and solutions. KJT looks forward to cooperating with you!