check

check

check

check

check

check

check

check

check

check

KJT high temperature proximity switch

A contactless sensor designed for extremely high temperature industrial environments can stably and accurately detect the presence and location of metal objects under high temperature conditions. With its excellent temperature resistance and anti-interference ability, this product is widely used in various industrial automation production, helping to improve intelligent manufacturing and production efficiency.

Features

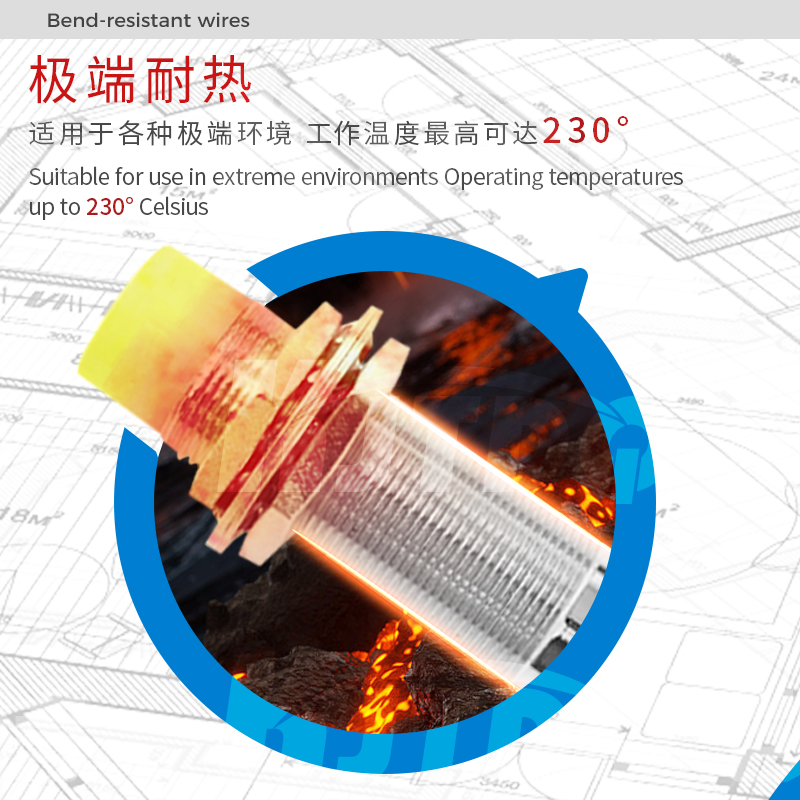

1. High temperature resistance design: It has excellent temperature resistance and can operate stably at temperatures up to 230°C or even higher, suitable for various high temperature industrial environments.

2. Electromagnetic induction principle: non-contact detection technology based on eddy current induction can quickly and accurately induce metal objects without physical contact.

3. High-precision detection: Provides extremely high repetition accuracy and fast response time to ensure real-time monitoring on high-speed automated production lines.

4. High reliability: Shows excellent anti-interference performance in harsh environments, can withstand challenges such as high humidity, dust, oil and pollution, and maintain long-term and stable operation.

5. Multiple specifications and temperature ranges: Provides a variety of size choices to meet different industrial application needs, and has a diverse installation method to facilitate adapting to complex industrial scenarios.

Advantages

1. Excellent high temperature resistance: This proximity switch can operate for a long time in a high-temperature environment without being affected by temperature fluctuations, ensuring the continuity and safety of production.

2. Contactless detection extends service life: Since there is no need to contact the object directly, the sensor wear is avoided, thereby greatly extending the service life of the product and reducing maintenance needs and downtime.

3. Efficiency and precision: The proximity switch has high precision and fast response capabilities, and can quickly identify metal objects in an automated production line to ensure efficient production.

4. Anti-environmental interference: Whether in high temperature, humidity, dust or other harsh working environments, the sensor can still maintain stable detection effect and has strong anti-interference ability.

5. Adapt to diverse application needs: Provide a variety of specifications and models for different industrial needs to meet the usage requirements of various special scenarios, with good compatibility and adaptability.

Application scenarios

1. Steel manufacturing: used to detect the position and movement of steel in high-temperature environments to ensure the safety and efficiency of the production process.

2. Glass manufacturing: In the high-temperature glass production line, accurately detect the position and movement of the finished glass products to help improve the level of automation.

3. Metallurgical Industry: In high-temperature equipment such as smelting furnaces and steel rolling mills, the status of metal materials is detected to ensure the accuracy and timeliness of production.

4. Automobile manufacturing: Suitable for high-temperature operations such as welding and spraying, monitoring the position and operating process of metal parts in real time, and improving the accuracy of automated production.

5. Automated production line: widely used in various mechanical manufacturing and automation equipment to ensure the smooth operation of intelligent production lines.

KJT high-temperature sensing proximity switch has become an indispensable core component in industrial automation through high-precision detection capabilities and excellent high-temperature resistance. It is especially suitable for application scenarios that require long-term stable operation in high-temperature environments.